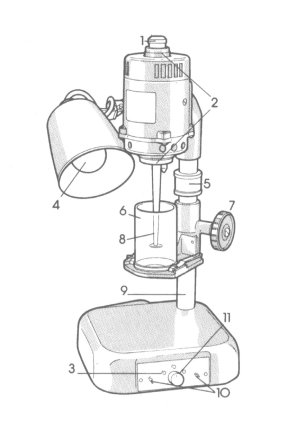

The Latex Rubber Test Machine has a highly reliable series wound motor which is electronically controlled and incorporates a feedback system to accurately maintain the selected speed.

It comes complete with visual confirmation in the form of colored LEDs and is supported by a matt black aluminium bracket on a chrome plated column.

The glass (synthetic) or perspex (natural) beaker is retained on its aluminium table.

Height is adjustable.

The apparatus is mounted on hard sponge rubber pads set into the black stove-enamelled cast iron base.

The unit is fully protected for use in tropical climates.

Motor bearings are sealed for life.

Height Setting

The hand wheel (7) lowers the beaker from the paddle by rack and pinion movement. This enables the user to set the depth between the paddle and the base of the beaker to exactly 13mm. A distance piece is supplied with the spare parts. With the distance piece in position between the paddle and the beaker, the adjustable stop (5) is set by means of two screwed caps which prevent the table from being too high. It is not necessary to alter this until a new container is used. The container is held in position by two chromed plated phosphor bronze clips.

Speed Control

The speed is factory set to 14,000 RPM. When switched on, the electronic circuitry automatically brings the unit to the correct speed (green LED). The feedback circuit maintains this speed at 14,000 ±200 RPM, within the stated voltage range.

Note

The voltage temperature compensation control (11) provides slight adjustment in the event of drift due to excessive input voltage or change in temperature. It must only be altered in conjunction with a tachometer to reset the shaft speed (remove top end cap (1) to gain access to shaft end).

The original MK1 latex mechanical stability test machine incorporated a vibrating reed arrangment in order to set the correct 14,000 rpm test speed.

The MK1 latex test machine was developed for the Dunlop Rubber Company in Birmingham United Kingdom.

S2T Group Ltd

125 High Road

North Weald

Essex

CM16 6EA

UK

Tel +44 1992 878 152